- MARUSHIGE SHIKO Japan’s only supplier of Water Transfer Paper

- Contact Us Phone: +81-568-31-7454 Fax: +81-568-34-4171 Adress 1-1-1, Kachigawacho,

Kasugai City, Aichi 486-0945 Japan

FactoryNEWS&FAQ

- These videos provided below will go some way toward helping you understand

our processes. The file size is 7 MB, max..

Receiving&Quality Check

- Received materials are stored in an automated warehouse and samples of

each consignment are checked for quality.

Processing

Special processing in the calender machine, based on our proprietary technology, is applied to both sides of the paper to improve surface smoothness.

- This picture shows the drying zone of the No. 3 Coating Machine.

- FUTEC, a plain surface inspection system, is used to check for small flaws, dark spots, and streaks, and then a marker seal is applied.

- The LM labeling machine automatically put a pink label on the place

where it detects a flaw.

Then an operator of the next process of cutting pull out the sheet of

paper with the pink label.

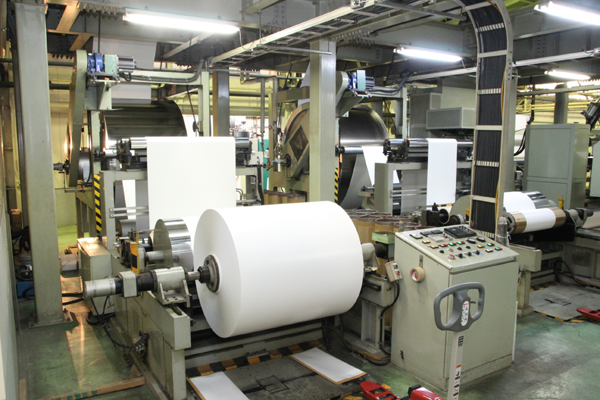

Rotary cutter

Rolls are cut into sheets by the rotary cutter. Two rotary cutters are used.

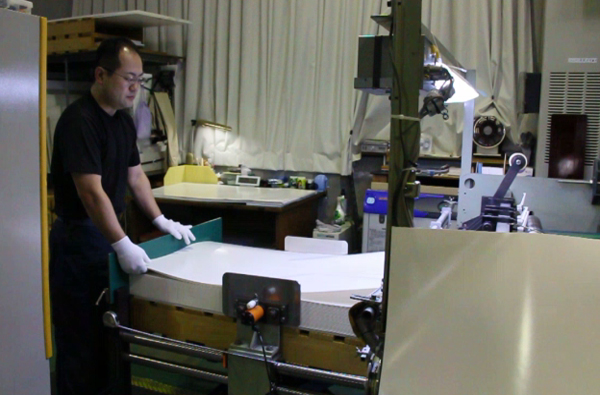

Cutting

The sheets are cut to the specified size using a cutting machine.Two cutting machines are in operation.

Cutting

Stacks of 500 sheets are prepared and transferred by belt conveyor to the automatic wrapping machine after two corners have been cut.

Automated Baling

Paper wrap is automatically applied by the YURIPAO wrapping machine, and the wrap is taped to the finished product at the same time.

- The product is automatically packed by wrapping paper and taped

simultaneously. Then the label machine put a product label on it and finally it is

laid on the pallet one by one.

Stored in Warehouse Racks

- The finished products are stored in mobile racks in the warehouse and sorted

by type and size.

Banner space

Marushige Shiko Co., Ltd.

1-1-1, Kachigawacho, Kasugai City, Aichi 486-0945 Japan

Phone: +81-568-31-7454

Fax: +81-568-34-4171

water@transfer-paper.jp